Ink

An ink is a liquid containing various pigments or dyes used for coloring a surface to render an image or text. It is used for drawing or writing with a pen or brush. Thicker inks, in the form of a paste, are used extensively in letterpress and lithographic printing.

Types of ink

Early varieties of ink include Egyptian ink, various natural dyes made from metals, the husk or outer covering of nuts or seeds, and sea creatures like the squid (known as sepia). India ink is black and originated in Asia. Walnut ink and iron-gall nut ink were made and used by many early masters to obtain the golden brown ink used for drawing.

Pigmented inks

Pigmented inks contain other agents that ensure adhesion of the pigment to the surface and prevent it from being removed by mechanical abrasion. These materials are typically referred to as binding agents (in water-based inks) or resins (in solvent-based inks).

Pigmented inks are advantageous when printing on paper because the pigment stays on the surface of the paper, and less of it soaks through the paper. Consequently, less ink needs to be used to create the same intensity of color.

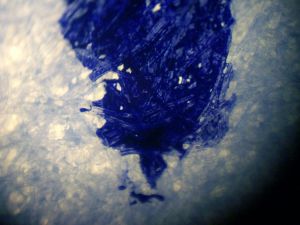

The pigments contain the different colors and are the main components of ink. The size of the pigment is very important for the ability of diffuse in the solution inks. Qualities such as hue, saturation, and brightness are inherent in the ink, and these qualities vary, depending on the source and type of pigment.

Dyes in inks

Dyes, however, are generally much stronger and can produce more color of a given density per unit of mass. However, because dyes are dissolved in the liquid phase, they have a tendency to soak into paper, thus making the ink less efficient and also potentially allowing for the ink to bleed at the edges, producing poor-quality printing.

To circumvent this problem, dye-based inks are made with solvents that dry rapidly or are used with quick-drying methods of printing, such as blowing hot air on the fresh print. Other methods to resolve this include harder paper sizing and more specialized paper coatings. The latter is particularly suited to inks that are used in non-industrial settings (and thus must conform to tighter toxicity and emission controls), such as inkjet printer inks, include coating the paper with a charged coating. If the dye has the opposite charge, then it is attracted to and retained by this coating, while the solvent soaks into the paper. Cellulose, the material that paper is made of, is also naturally charged, and so a compound that complexes with both the dye and the paper surface aids retention at the surface. Such a compound in common use in ink-jet printing inks is polyvinyl pyrrolidone.

An additional advantage of dye-based ink systems is that the dye molecules interact chemically with other ink ingredients. This means that they can benefit more than pigmented ink from optical brighteners and color-enhancing agents designed to increase the intensity and appearance of dyes. Because dyes get their color from the interaction of electrons in their molecules, the way in which the electrons can move is determined by the charge and extent of electron delocalization in the other ink ingredients. The color emerges as a function of the light energy that falls on the dye. Thus, if an optical brightener or color enhancer absorbs light energy and emits it through or with the dye, the appearance changes, as the spectrum of light re-emitted to the observer changes.

A disadvantage of dye-based inks is that they can be more susceptible to fading, especially when exposed to ultraviolet radiation as in sunlight.

History of ink

Approximately 5,000 years ago, the Chinese developed ink for blackening the raised surfaces of pictures and texts carved in stone. This early ink was a mixture of soot from pine smoke, lamp oil, and gelatin from animal skins and musk. Other early cultures also developed inks (of many colors) from available berries, plants and minerals.

In an article for the Christian Science Monitor, Sharon J. Huntington describes these other historical inks:

About 1,600 years ago, a popular ink recipe was created. The recipe was used for centuries. Iron "salts," such as ferrous sulfate (made by treating iron with sulfuric acid), was mixed with tannin from gallnuts (they grow on trees) and a thickener. When first put to paper, this ink is bluish-black. Over time it fades to a dull brown.

Scribes in medieval Europe (about AD 800 to 1500) wrote on sheepskin parchment. One 12th century ink recipe called for hawthorn branches to be cut in the spring and left to dry. Then the bark was pounded from the branches and soaked in water for eight days. The water was boiled until it thickened and turned black. Wine was added during boiling. The ink was poured into special bags and hung in the sun. Once dried, the mixture was mixed with wine and iron salt over a fire to make the final ink.

In the fourteenth century, a new type of ink had to be developed in Europe for the printing press by Johannes Gutenberg. Two types of ink were prevalent at the time: the Greek and Roman writing ink (soot, glue, and water) and the twelfth-century variety (composed of ferrous sulfate, nutgall, gum, and water). Neither of these handwriting inks could adhere to printing surfaces without creating blurs. Eventually an oily, varnish-like ink made of soot, turpentine, and walnut oil was created specifically for the printing press. Ink is made from plants.

Modern Ink Applications

Up to a few years ago, consumers had very little interest in ink other than to buy refills for their pens. Fountain pens became a novelty as the disposable ball point pen took over the market. The introduction of home computing led to home printing. Today it is rare to find a residence or business that does not have a printing capability. As a result, buying "ink" in the form of a cartridge or having that cartridge refilled at an inkjet island in a local mall has become a part of the day-to-day shopping experience, just as buying a bottle of ink was common 50 years ago.

Ink refilling services for printer cartridges are offered by large, official printing companies as well as smaller, "unofficial" refill companies. Customers can often cut printing costs by using refill services from a refill company.

Soy ink

Soy ink is a type of ink made from soybeans. Compared to traditional, petroleum-based ink, soy-based ink has the following advantages.

- It is more environmentally friendly,

- it is available in brighter colors,

- it improves the life span of the printers,

- it makes it easier to recycle paper, and

- it is more economical in the long run.

History of soy ink

Soy ink is a form of non-food soy. It is an environmentally friendly, healthy, and safe approach to printing that takes only a small amount of energy to make. In fact, soybeans only use about 0.5 percent of the total energy that is needed to create the ink. In the late 1970s, the Newspaper Association of America was looking for different ways to make ink, rather than by using the standard petroleum-based ink. Rising prices for petroleum and quarrels with OPEC countries were reasons they wanted to find a more reliable and cost efficient method of printing.

After testing over 2,000 different vegetable oil formulations, researchers came up with a solution. In 1987, soybeans were chosen to make ink because of their abundance and low cost. With soy bean ink, those who tested it found no threat to the air or to the environment. In addition, approximately half of the soybeans that are grown in the United States do not even need watering, which is why using soybeans for ink can actually benefit the environment. Another benefit to soy inks are its low levels of VOCs, (volatile organic compounds) which can help with air pollution by minimizing emissions.

Production

To make soy ink, soybean oil is slightly refined and then blended with pigment, resins, and waxes. Even though soybean oil is also known as vegetable oil which can be eaten, soy ink is not edible because the pigments that are mixed in with the oil are the same ones that are used in petroleum-based inks. The pigments and other additional chemicals added to create soy ink explain why it is not 100 percent biodegradable or edible.

Soy ink is made from soybean oil which has an innate clearness to it. Petroleum-based ink is not clear, and other vegetable oils are not as clear as soybean oil making it harder to obtain bright colored ink. For this reason, newspapers use soy ink regularly, especially for color because it creates a sharper and brighter image.

Benefits and disadvantages

Soy ink is also a helpful component in paper recycling. It helps in this process because the soy ink can be removed more easily than regular ink can be taken out of paper during the de-inking process of recycling. This allows the recycled paper to have less damage to its paper fibers and have a brighter appearance. The waste that is left from the soy ink during the de-inking process is not hazardous and it can be treated easily through the development on modern processes.

Unfortunately, soy ink is not a perfect solution to the problems associated with the production of ink. For example, it cannot be used in ballpoint pens and personal printers. These are some of the many restrictions of soy ink. One major problem with soy ink is that the ink rubs off quite easily. This creates challenges for printing presses. However, despite this flaw, soy ink sales remain large, and newspapers are still the biggest buyers. Within the last 15 years since its development, the product manages to sell about 90 percent of the country’s daily newspapers with circulations of more than 1500. Today about one quarter of commercial printers in the United States operate using soy ink.

Invisible ink

Invisible ink is a substance used for writing, which is either invisible on application, or soon thereafter, and which later on can be made visible by some means. The use of invisible ink is a form of stenography, and has been used in espionage. Other uses may include property marking, hand stamping for readmission, and marking for the purpose of identification in manufacturing.

Application and use

Invisible ink is applied to a writing surface with a fountain pen, toothpick or even a finger dipped in the liquid. Once dry, the surface should appear blank and of similar texture as surrounding material.

A cover message should be written over the invisible message, since a blank sheet of paper might arouse suspicion that an invisible message is present. This is best done with a ballpoint pen, since fountain pen writing may 'run' when it crosses a line of invisible ink, thus giving a clue that invisible ink is present. Similarly, invisible ink should not be used on ruled paper, since it may alter or streak the color of the lines.

The ink is later made visible by different methods according to the type of invisible ink used. This may be by heat, by application of a chemical appropriate to the ink used, or without development by viewing under ultraviolet light. The invisible inks which depend on a chemical reaction generally depend on an acid-base reaction (like litmus paper) similar to the blueprint process. Developer fluids may be applied using a spray bottle, but some developers are in the form of vapors, e.g., ammonia fumes for developing phenolphthalein ink.

Commercial invisible ink

One can obtain toy invisible ink pens which have two tips - one tip for invisible ink writing, and another tip for developing the ink. Also, invisible ink is sometimes used to print parts of pictures or text in books for children to play with, particularly while they are traveling. A "decoder pen" is included with these books and children may rub this pen over invisible parts of texts or pictures, thus revealing answers to questions printed in regular ink or completing missing parts of pictures.

Other ink pens can be obtained commercially that fluoresce when illuminated with a UV (ultraviolet) light. These inks are simply applied and then identified using a black light or other UV light source. These inks are invisible to the naked eye and are only revealed when illuminated. They are widely used for property marking as a crime countermeasure.

There is a commercially available red invisible ink which is only invisible when applied to certain types of surfaces, but visible on others.

Some vendors now offer invisible ink for use in computer inkjet printers. Such inks are usually visible under ultraviolet light. Typical uses include printing information on business forms for use by the form processor, without cluttering up the visible contents of the form. For example, some United States Postal Service mail sorting stations use UV-visible ink to print bar codes on mailed envelopes giving routing information for use by mail handling equipment further down the line before delivery.

Very rarely, invisible ink has been used in art. It is usually developed, though not always. There are artists who use the effect in conjunction with Invisible and other reactive inks and paints to create a variety of effects when used in conjunction with UV lights.

Invisible ink types

Inks developed by heat

Some of these are organic substances that oxidize when heated, which usually turns them brown. For this type of 'heat fixed' ink, any acidic fluid will work. As a rule of thumb, the most secure way to use any particular ink is by diluting it - usually with water - near to the point when it begins to get difficult to develop.

- Milk

- Lemon, apple or orange juice

- Onion juice

- Sugar solution

- Diluted honey

- Diluted cola drink

- Vinegar or wine

- Soap water

The writing is made visible by heating the paper, either on a radiator, by ironing it, or by placing it in an oven. A 100 Watt light bulb is less likely to damage the paper.

Inks developed by chemical reaction

In most cases, one substance changes color when mixed with an acid or base.

- Phenolphthalein, developed by ammonia fumes or sodium carbonate.

- Phenolphthalein is a pH indicator that turns pink in the presence of a base such as ammonia.

- Vinegar, revealed by red cabbage water.

- Vinegar contains acetic acid that affects the pH indicator in red cabbage water.

- Ammonia, developed by red cabbage water.

- Copper sulfate, developed by sodium iodide.

- Copper sulfate, developed by sodium carbonate.

- Copper sulfate, developed by ammonium hydroxide.

- Lead(II) nitrate, developed by sodium iodide.

- Iron sulfate, developed by sodium carbonate.

- Iron sulfate, developed by potassium ferricyanate.

- Cobalt chloride, developed by potassium ferricyanide.

- Copper sulfate, developed by potassium ferricyanide.

- Iron sulfate, developed by sodium sulfide.

- Starch, developed by iodine solution (ink turns dark blue, paper turns light blue).

- Lemon Juice, developed by iodine solution (ink turns white, paper turns light blue).

- Sodium Chloride (table salt), developed by silver nitrate.

Inks visible under ultraviolet light

Some inks glow faintly (fluoresce) when under an ultraviolet lamp. This is a property of many substances. There are commercially available inks that glow very brightly when illuminated using a black light or UV light. Invisible inks with fluorescent properties can be obtained in a variety of colors and even have formulations for non-porous surfaces so they can be used on glass, plastics, etc.

Other inks work in a near opposite way by absorbing ultraviolet light. When they are used on fluorescent paper, the written-on areas fluoresce less than the surrounding paper area when under an ultraviolet lamp. This is especially a property of inks with a yellow tint.

Security marker pens with fluorescent ink may also be used to invisibly mark valuable household items in case of burglary. The owner of a recovered, stolen item which has been marked in this way can be traced simply by using an ultraviolet lamp. Items can also be marked for a variety of property marking purposes and identification. They can also be used in readmissions such as hand stamping.

Inks that disturb the surface of paper

This includes virtually all invisible inks, but pure distilled water can also be used in this way. Application of any fluid will disturb the paper surface fibers or sizing.

Fumes created from heating iodine crystals will develop the writing, which will appear brown because the iodine sticks preferentially to the disturbed areas of the paper. Exposing the paper to strong sunlight will return the writing to its invisible state, as will using a bleach solution.

Slightly dampening paper with a sponge, or by steam and then drying it before writing a message, will prevent writing from being developed by this method. But overdoing dampening will result in telltale paper cockling.

Interception of secret messages

Any invisible ink can be made visible by someone who is sufficiently determined, but the limitation is generally time available and the fact that one cannot apply hours of effort to every single piece of paper. Successful use of invisible ink depends on not arousing suspicion.

Telltale signs of invisible ink, such as pen scratches from a sharp pen, roughness or changed reflectivity of the paper (either more dull or more shiny, usually from using undiluted ink) can be obvious to a careful observer who simply makes use of strong light, a magnifying glass and their nose. Also, key words in the visible letter, such as 'red cabbage' or 'heat', in an odd context may alert a censor to the use of invisible ink. Invisible ink should not be used with glossy or very smooth paper types, since the sizing of these papers prevents ink from being absorbed deep into the paper and it is easily visible, especially when the paper is examined under glancing light. There are, however, commercially available inks for non-porous surfaces that are only visible under ultraviolet light and are otherwise virtually invisible on these kinds of surfaces.

Using either ultraviolet light or an iodine fume cupboard, messages can be quickly screened for invisible ink and also read without first permanently developing the invisible ink. Thus, if a censor uses this method to intercept messages, he may then let the letter be sent to the intended recipient who will be unaware that the secret message has already been intercepted by a third party.

A "screening station" could theoretically involve visual and olfactory inspection, an examination under ultraviolet light and then the heating of all objects in an oven before finally trying exposure to iodine fumes. In theory, some invisible inks may even show up using a camera sensitive to infrared light.

Properties of an "ideal" invisible ink

Most invisible inks are insecure. World War II SOE agents were trained not to risk their lives through reliance on insecure inks, most of which inks were of World War I vintage. The SOE training manual identified the following properties of the "ideal" invisible ink:

- Very water soluble, i.e., non-greasy.

- Non-volatile, i.e., no pronounced smell.

- Not depositing crystals on paper, i.e., not easily seen in glancing light.

- Invisible under ultraviolet light.

- Does not decompose or discolor the paper, e.g., not silver nitrate.

- Unreactive with iodine, or with any of the other usual developers.

- Potential developers for the ink should be as few as possible.

- Should not develop under heat.

- Easily obtainable and has at least one plausible innocent use by the holder.

- Not a compound of several chemicals, as this would contradict "7."

In practice, "6" and "9" are usually incompatible. The SOE was known to supply special inks to their field agents, rather than depend on improvisation from obtainable everyday chemicals.

Invisible inks are not inherently "secure," but this has to be balanced against the fact that it is technically difficult to carry out mass screening of posted letters. It is easier to perform large-scale undetected screening of millions of electronic communications than it is to manually inspect even a small fraction of conventional posted letters. Apart from in dictatorships with large numbers of personnel employed to spy on their fellow nationals, inspection of posted mail can only be used in particular situations, for example focusing on the letters of a particular suspect or the screening of letters entering and leaving a particular facility.

As an indication of security, most of the inks mentioned here were already known by the end of World War I. The U.S. Central Intelligence Agency requested (successfully) in 1999 that World War I era invisible ink technology remain exempt from mandatory declassification, based on their disputed claim that invisible ink was still relevant to national security.

ReferencesISBN links support NWE through referral fees

- Audin, Maurice. "A History of Technology and Invention," 630

- Sharon J. Huntington, "Think Ink!" Christian Science Monitor, (September 21, 2004) retrieved January 17, 2006.

- SOE Syllabus: Lessons in Ungentlemanly Warfare, World War II. Surrey, UK: Public Record Office, 2001.

External links

All links retrieved March 3, 2018.

- Sarah Aguirre, How to Remove Ink From Clothes TheSpruce.com

- Soy ink

- Katherine Pfleger The formula for invisible ink will remain classified as part of the CIA's effort to protect national security. Really. St. Petersburg Times, June 23, 1999.

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.